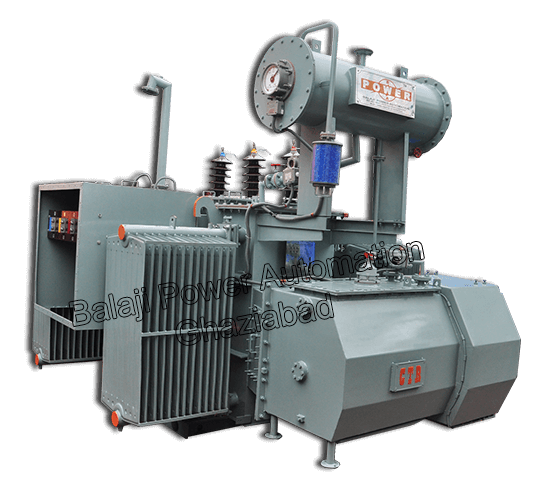

Power Transformer

Power Transformers

Balaji Power Automation is recognized as a high quality power transformer manufacturers and is listed collectively of the highest makers, Suppliers and Exporters of Power Transformer.

We manufacture power transformers as per IS 2026, IS 6600, IEC 60076 & IS 1180 standards.

● Power Transformer manufacturing range: Upto 10 MVA, 66kV

● Method of cooling: Oil Natural Air Natural (ONAN) / Oil Natural Air Forced (ONAF)

RANGE : Upto 10 MVA in 11, 22, 33, 66 KV Class.

Technical Specifications:

| Power Rating | Upto 10,000 KVA (10 MVA) |

| Input Voltage(HV Side) | Upto 66 KV |

| Output Voltage(LV Side) | Upto 11 KV |

| Type | Hermetically Sealed / Free Breathing |

| Cooling Method | Oil Cooled / Air Cooled |

| Rated Frequency | According to Client’s requirement |

| Tap Changing Method | On-Load / Off-Load |

| Vector Group | According to Client’s requirement |

| No-Load Losses | According to Client’s requirement |

| Load Losses | According to Client's requirement |

|---|---|

| Percentage Impedance | According to Client’s requirement |

| Applicable Standard | IS 1180, 2026 & IEC 60076 |

Standard Fitting:

- Rating & Diagram plate

- Lifting lugs

- Oil Conservator with drain plug

- Oil Level indicator

- Top-filter Valve

- Silica gel breather

- Cooling radiators

- Earthing terminals

- Thermometer pocket

- Air release hole with plug

- Explosion vent with diaphragm

- Inspection cover.

- Drain –cum-bottom-filter valve

- Uni / Bi- directional rollers

Advantage Power Transformer:

- Help to improve the efficiency of the electrical power system

- Help to improve the quality of the electrical power (They do this by reducing the amount of power that is lost in transmission and by providing a more stable voltage.)

Transformer Optional Parts (Charge Extra):

|

|

What is Power Transformer?

A power transformer is a device that transforms electrical energy from one form to another. It is an essential component of the electrical power grid, providing a link between generating stations and load centers. Transformers come in a variety of sizes and shapes, but all share the same basic principle of operation. There are three main types of power transformers:

- Step-up transformer: This type of transformer increases the voltage of the electrical energy.

- Step-down transformer: This type of transformer decreases the voltage of the electrical energy.

- Isolation transformer: This type of transformer provides electrical isolation between two circuits.

Application of Power Transformer:

- Industries,

- Power Generating Stations,

- Receiving Stations, Substations

- Railways

- Chemical

- Pharmaceuticals

- Steel

- Hydro Power Projects

- Textile

- Engineering

- Plastic

- Cement

- Refineries

- Mining

- Captive Power Projects

- Wind Mill Farms

- Construction Houses

- Pharma

- Electrical,

- Electronics,

- Renewable Energy,

- Automobile